AlgaePARC is a state-of-the-art research facility spanning 750 m2, strategically located within the experimental fields of Wageningen University. Comprising fully equipped analytical laboratory and pilot spaces, including two greenhouse compartments and outdoor areas, AlgaePARC is dedicated to advancing research in microalgal biomass production and biorefinery. AlgaePARC’s extensive infrastructure underscores its dedication to advancing research and innovation in microalgae and cyanobacteria, establishing itself as a leading institution in the field.

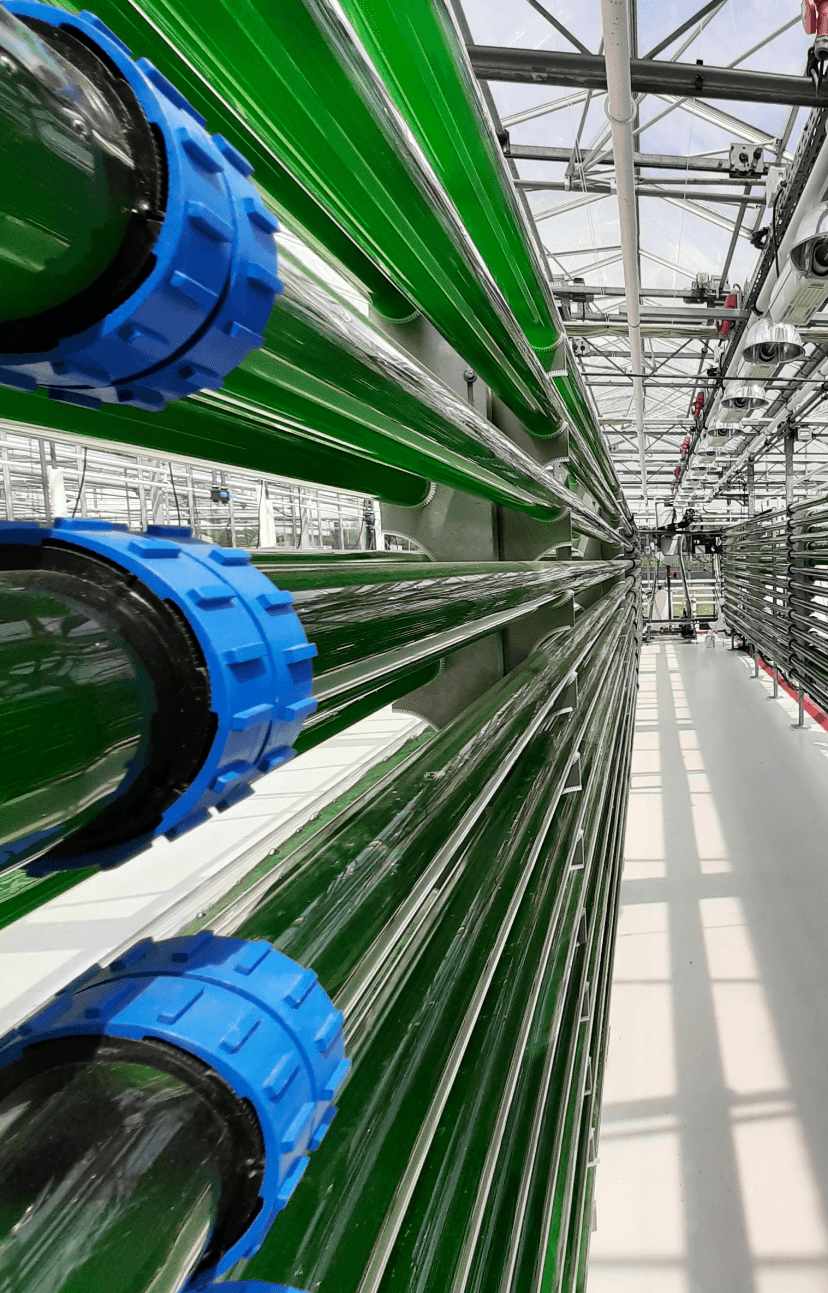

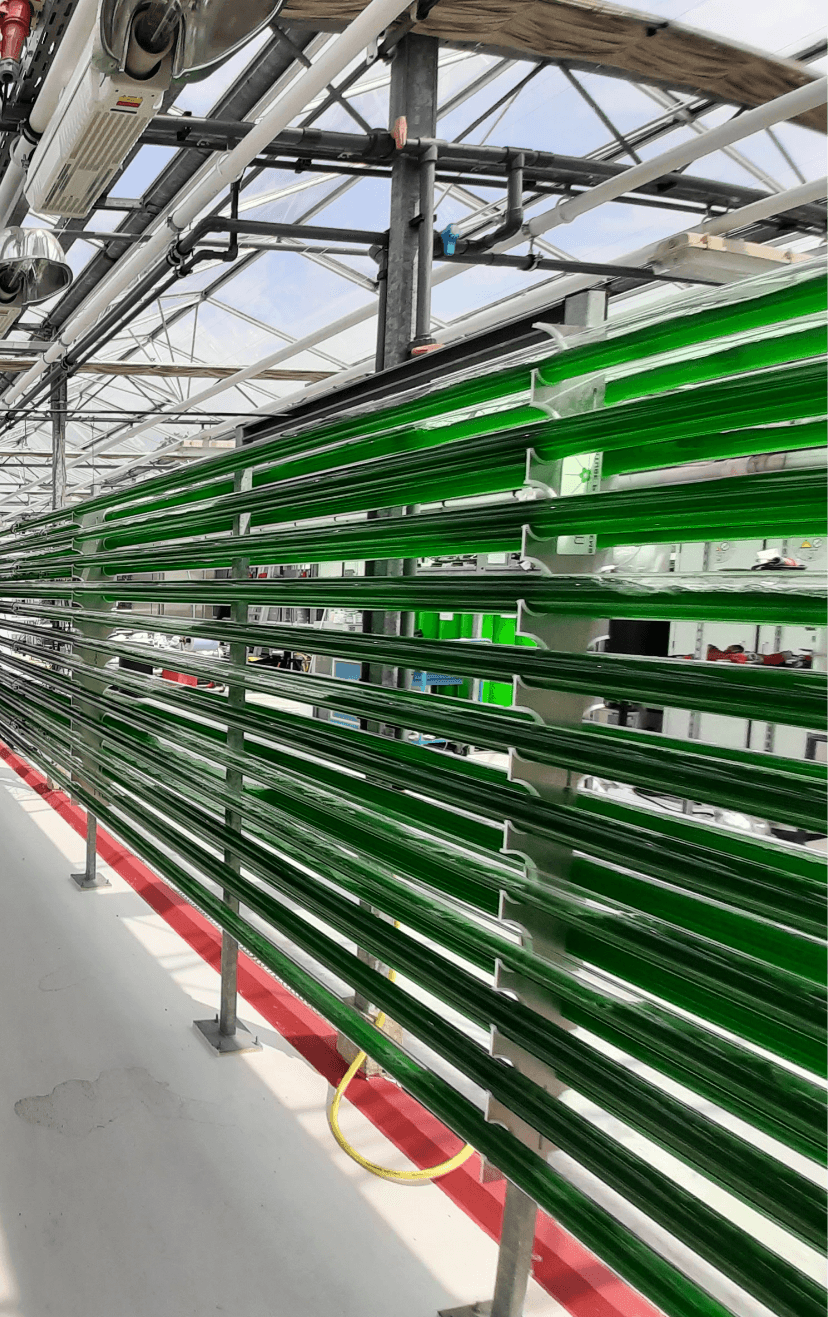

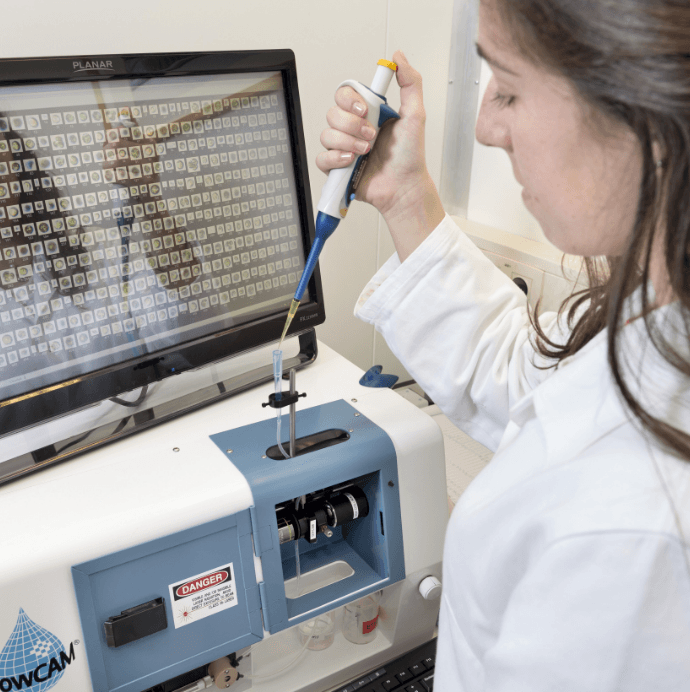

The indoor infrastructure accommodates various reactor types (tubular, flat panel) and sizes to facilitate preliminary studies,(25L, 250L) generate biomass for pilot-scale reactors(1700L), and maintain year-round production. Smaller systems enable initial screenings, physiological studies, and simulation of outdoor conditions for efficient strain characterization and production process development. The facility houses two industrially relevant LGem® 1700L tubular photobioreactor for commercial-scale simulation.

Food Safe and GMO Facility

The indoors pilot plant hosts genetically modified microalgae cultivation in the closed vertical LGem® 1700L tubular photobioreactor designed for industrial-like operation and control. This reactor operates year-round, supporting research and biomass production for biorefinery and product development.

At AlgaePARC, our advanced downstream process equipment is tailored for crucial purification and isolation steps in bio-based product development. This includes cutting-edge devices for filtration, chromatography, centrifugation, and other advanced separation techniques, along with specialized systems for efficient drying and precise formulation of the final product. Emphasizing the paramount importance of the downstream process, AlgaePARC is dedicated to upholding the highest standards of quality, purity, and yield. This commitment ensures the successful creation of bio-based products that meet the stringent requirements of modern biotechnological applications.

AlgaePARC has evolved into an innovation hub for SMEs and startups in the field of biotechnology over the past five years. This expansion of its impact beyond algal applications demonstrates its importance as a resource for the broader biotechnology community. Here are some key points about this development:

AlgaePARC has diversified its services to accommodate projects from various branches of biotechnology. This diversification reflects its adaptability and relevance in supporting a wide range of research and development efforts.

AlgaePARC has actively welcomed SMEs and startups, recognizing their potential to drive innovation and economic growth in the biotechnology sector. By providing access to its facilities, AlgaePARC has played a crucial role in accelerating these businesses.

The official receipt of funds from the European Regional Development Fund (EFRO) in 2022 marks a significant milestone. These funds enabled the development of AlgaePARC 2.0, an updated infrastructure that offers enhanced flexibility to meet various research goals. This upgrade includes state-of-the-art equipment, expanded capacity, and improved research facilities.

By supporting the growth of SMEs and startups in the biotechnology sector, AlgaePARC is contributing to regional economic development and technological advancement. It can serve as a catalyst for innovation and entrepreneurship, driving job creation and economic prosperity in the region.

The emphasis on flexibility in the updated infrastructure (AlgaePARC 2.0) demonstrates a commitment to staying at the forefront of biotechnology research. This flexibility will allow AlgaePARC to adapt to evolving research needs and emerging technologies effectively.

AlgaePARC’s evolution into an innovation hub for SMEs and startups in biotechnology showcases its adaptability, commitment to fostering innovation, and contribution to regional development. The support from EFRO to enhance its infrastructure will likely further solidify its role as a key player in advancing biotechnological research and entrepreneurship in the region.

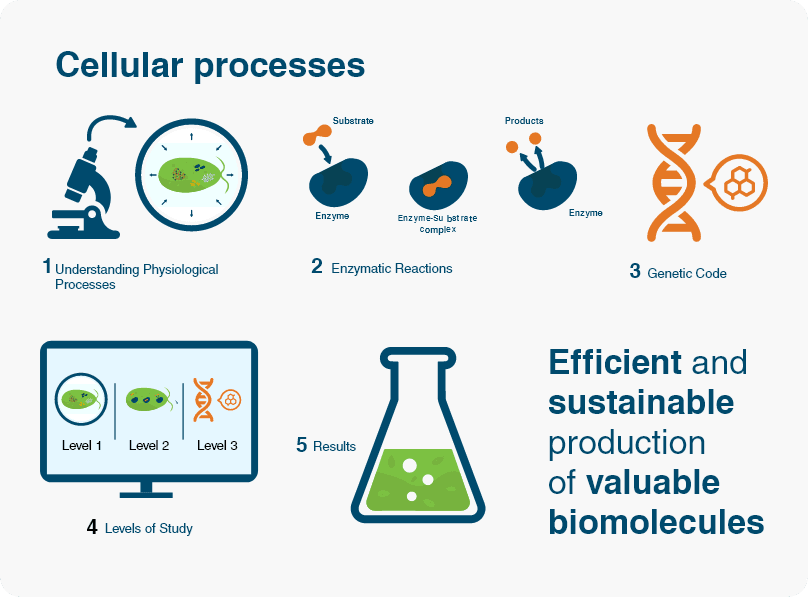

AlgaePARC continuously strives to advance our understanding of the physiological processes occurring in the cell leading to growth and the production of valuable biomolecules. Deeper understanding of these processes and their regulation under various cultivation conditions allows us to find targets for strain improvement and cultivation optimisation. Microalgae and cyanobacteria are performing many chemical reactions to grow and produce the different valuable compounds. These reactions are carried out by enzymes. Information with regards to which enzymes can be present in the cell is enclosed in the genetic code of each species. To provide insight into the complex network of processes that govern cell physiology, we study the cells at various levels.

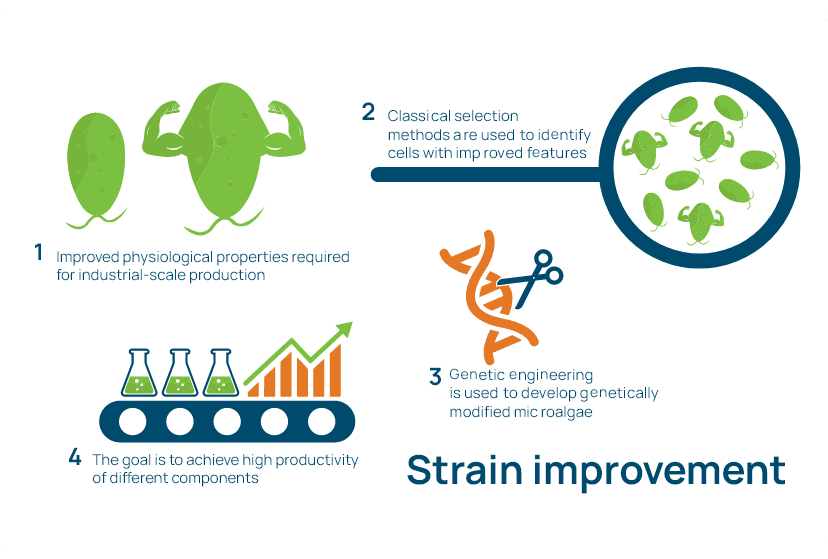

To achieve high productivity of different components, or to make microalgae more suitable for production at an industrial scale, improving of (industrially relevant) physiological properties of microalgae is often required. To this end we are focusing on strain development via classical selection methods (analogous to what was done in plant breeding, thus selecting the cells with improved features, and using them to make new populations). Also, at AlgaePARC we work on state-of-the-art genetic engineering technologies to develop genetically modified organisms.

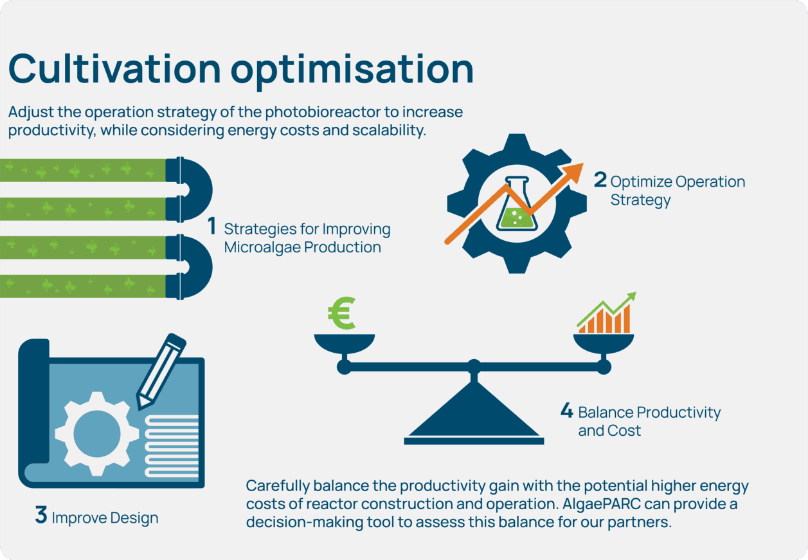

An important way to decrease the costs of microalgae production is by increasing the production rate of biomass and products in a photobioreactor. This can be done either by optimizing the operation strategy of the bioreactor or improving the design of the photobioreactor. Both will have implications for scale up. The productivity gain therefore must be carefully balanced with potential higher (energy) costs of reactor construction and operation ( a decision making tool we can provide to our partners, as we can perform this kind of assessment).

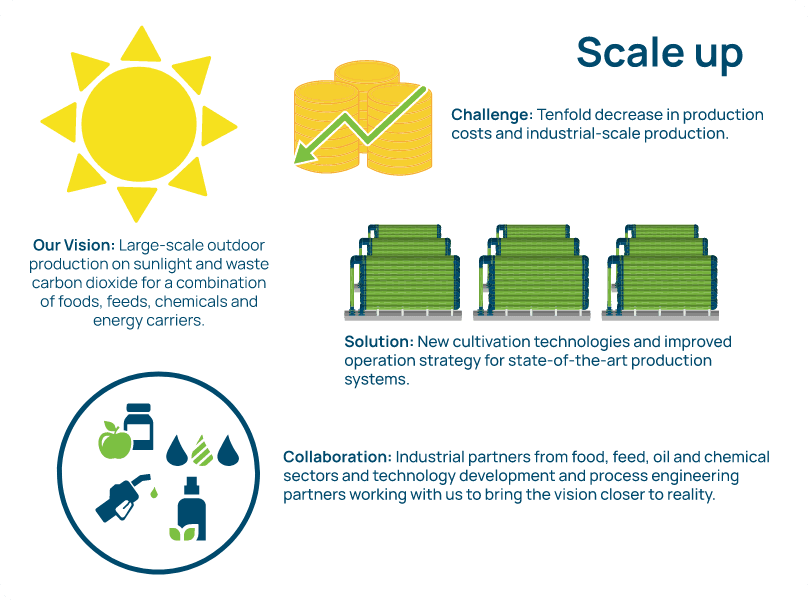

We envision a future of large-scale outdoor production on sunlight and waste carbon dioxide for a combination of foods, feeds, chemicals and energy carriers. For commercial production of algae for commodities, production costs should decrease tenfold and scale of production should increase to industrial scale. To bring this vision closer we are working hard on new cultivation technologies for large-scale production as well as improving the operation strategy of state-of the art production systems (we develop new reactor design, new operational strategies, we work with commercial systems also). We do this in close collaboration with industrial partners from the food, feed, oil and chemical sectors as well with partners working on technology development and process engineering.

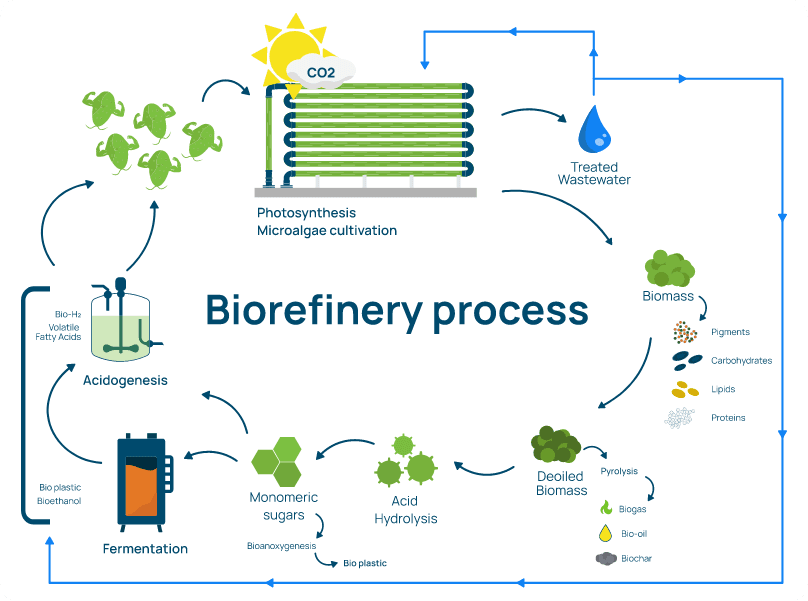

Biorefinery refers to the process of converting biomass into feedstocks that can be used in the manufacturing of a whole range of products for food, feed, fuel, materials, pharma and chemical applications. This approach is analogous to the refinery of crude oil where a range of products is manufactured from a single feedstock to optimize value. Currently, most biorefinery approaches only recover one or a few product types from plant materials.

Single components are derived from biological feedstocks (ranging from agricultural crops to straw and microalgae). In the extraction conditions, cells are completely destroyed and many of the other valuable ingredients (e.g. proteins, polysaccharides, vitamins) present in the biomass lose their functionality. Furthermore, this approach creates very complex mixtures of biomolecules, which make separation of valuable components a big challenge (often a financial burden to processes). AlgaePARC is currently exploring mild separation processes, in which the biomass is carefully disentangled. Mild separation enables us to obtain many more valuable biomolecules from the microalgal biomass. This enhances the economic value of the biomass, and at the same time has a positive effect on the ecological impact of the bioproducts that are developed. Moving from a ‘demolition’ towards a ‘disentanglement’ approach requires a biorefinery platform that includes a detailed characterization of the cellular structure (cell wall structure, composition, and location of the cellular components) and a combination of dedicated mild-separation processes (harvesting, cell disruption, extraction, and fractionation technologies).

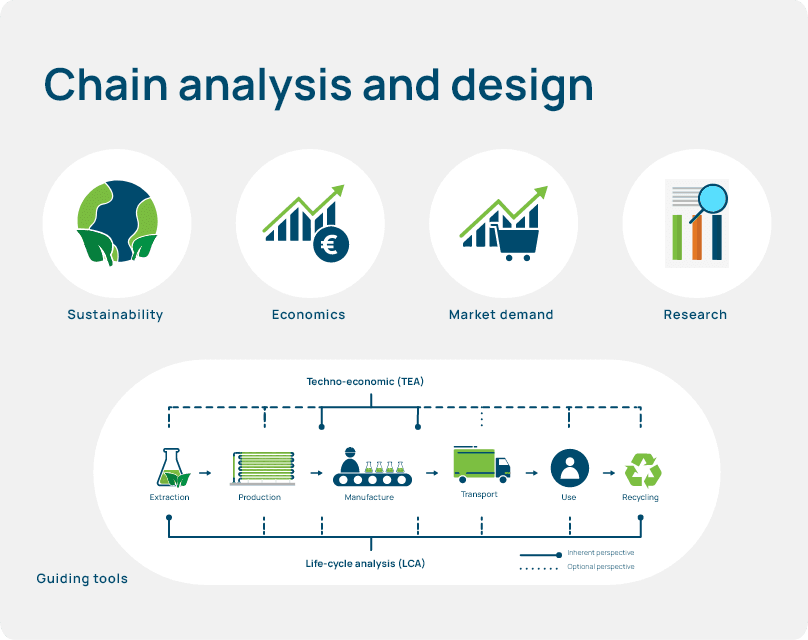

The business case of biobased products from microalgae requires chain sustainability with regard to economics, environmental and social aspects, offering a more sustainable solution than the bulk commodities available today. In addition, the economics should show the potential of the process and related products in the specific markets of interest. Commodities should meet market demand in terms of volume, constant supply, quality, safety, and reliability. Research lines on full production chains at larger scale will enable this sustainability d assessment and study potential implementation.

At AlgaePARC techno –economic (TEA) and life-cycle analysis (LCA) models are developed and continuously upgraded with own experimental data and experience. These models are used as a guiding tool to setting up new research programs at AlgaePARC and to advise our partners during their decision making processes.

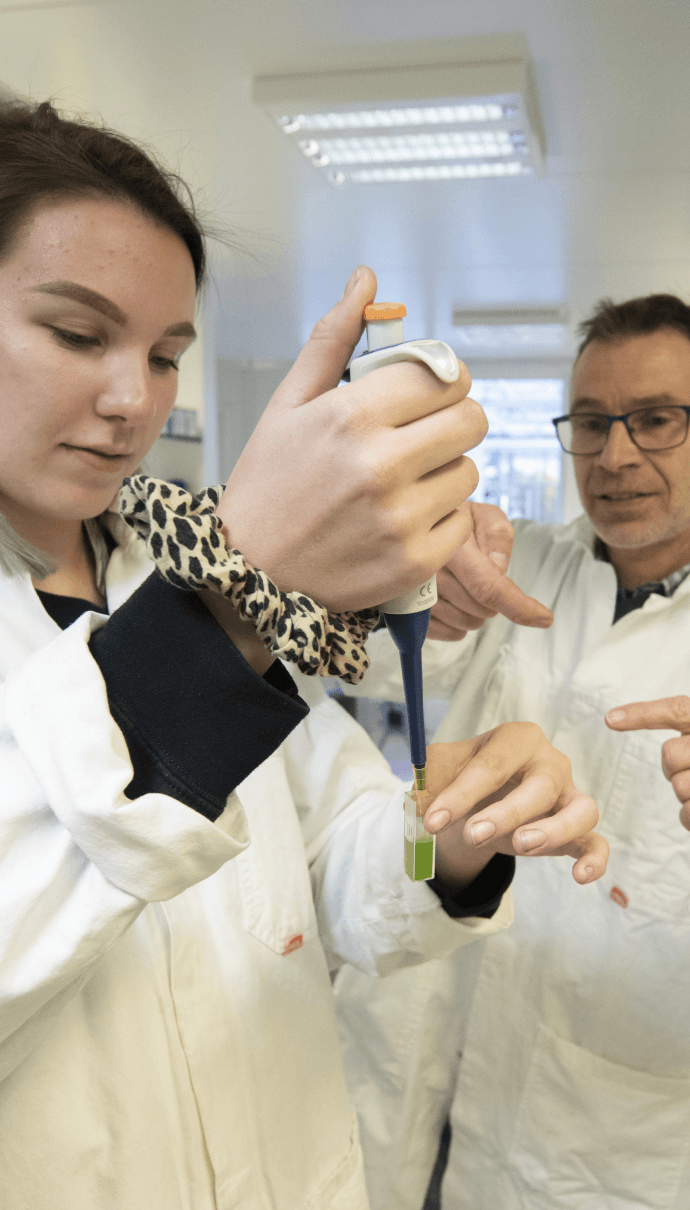

Education programs. AlgaePARC is a place to show that new technologies are possible. It is the place to understand how cells respond to real industrial conditions. Here, we guarantee that students will have access to state-of-the-art technology. AlgaePARC is a place providing the following benefits to WUR’s Educational programs.

As the activities in the algae field are increasing there is a serious need for adequately trained people. At AlgaePARC, 4 programs have been developed at different levels:

High school students: For high school students design classes and science assignments have been organized with an outreach of more than 2500 students so far.

BSc Biotechnology: Besides classes in algal physiology, students do a practical where they have to design a process to produce as much a s possible of an algal metabolite. In the practical’s the production strategies will be tested and compared.

MSc Biotechnology: a course is given on the design on production systems. This course is based on mathematical modelling Graduate course: a short and intensive course in fundamentals and design of photobioreactor systems for PhD students and bioprocess engineers. The 10 days course is a combination of courses and practicals in photobioreactor design. Digital learning material is used to support students in a case study on the design of photobioreactors for algal growth and production.

Advanced Summer Course: Since its inauguration, 7 summer schools on microalgae process design and 3 summer courses on microalgal biorefinery were organized. The aim of the courses is to provide the essential skills for designing optimal microalgae-based production processes, for both research and commercial purposes. The summer schools are targeted at PhD candidates, postgraduate and postdoctoral researchers, as well as professionals, who would like to acquire a thorough understanding of microalgal metabolism and photobioreactor design. Through lectures, digital cases and a photobioreactor practical, the participants learn: 1) how to describe microalgal metabolism quantitatively, 2) how to apply basic design principles and set up mass/energy balances for photobioreactors, 3) how to cultivate microalgae in fully controlled photobioreactors, and 4) how to integrate all acquired knowledge into optimal production strategies for microalgae biomass or secondary metabolites.